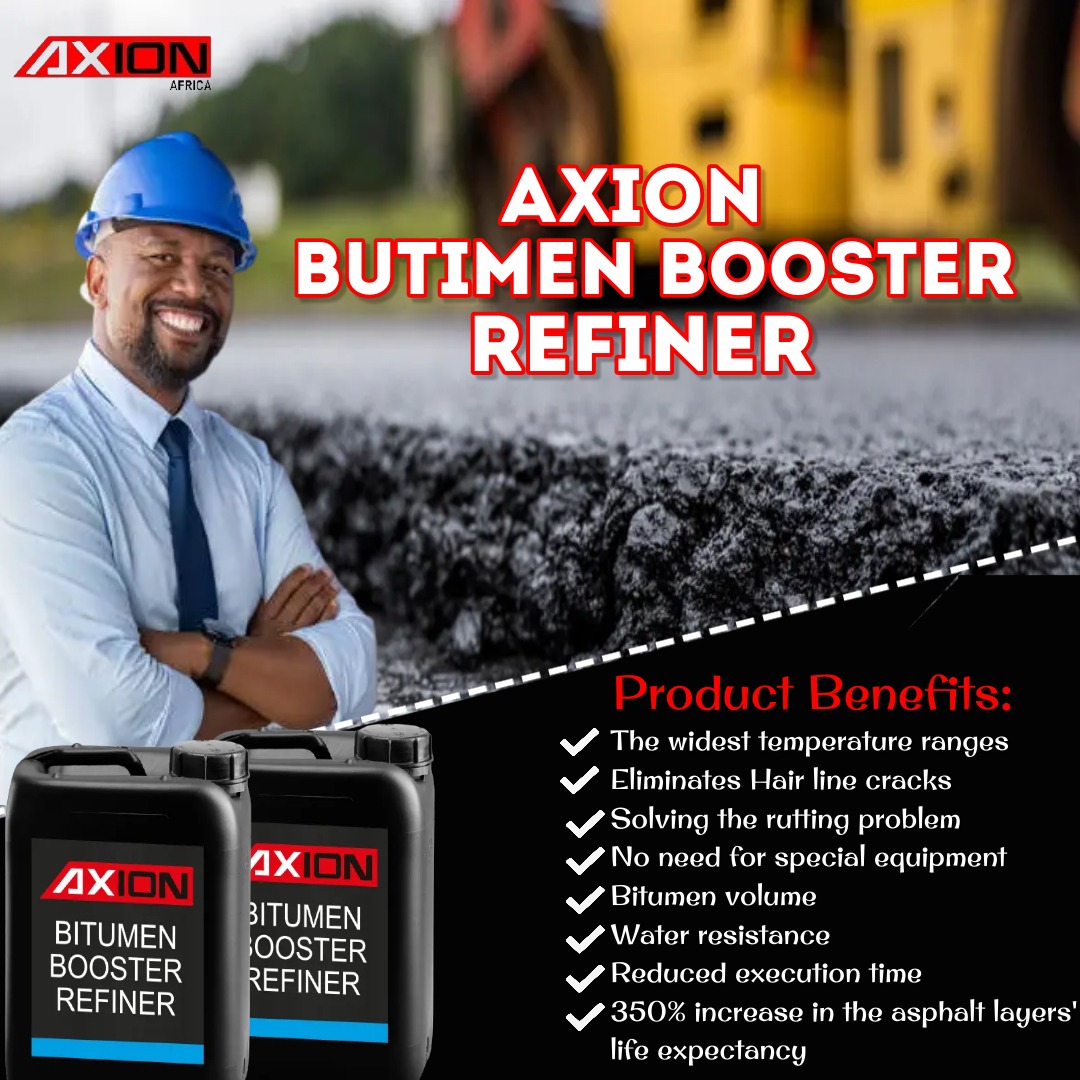

ABOUT AXION BITUMEN BOOST REFINER

A new industry with a standard of excellence.

Increase the volume of bitumen up to 30% saving more than it’s cost and increasing the contractor’s probability. Increase Strength, Decrease Costs

Our Bitumen Boost Refiner interacts with natural molecular structure of bitumen used in asphalt batching to substantial increase its strength, while adding higher resistance to the sun’s UV rays which deteriorates the strength of bitumen over time

APPROVED IN OVER 75 COUNTRIES INCLUDING THE EUROPEAN COMMUNITY:

It is the only binder in the world that makes the bitumen water resistant. All these features benefit both the end user and increases the profitability of the contractor.

Product Features/ Advantages:

BBR AND THE STABILITY CURVE: Bitumen is unstable due to the fact that it is the end product of many types of crude oils. – For the first time, in the history of bitumen, the use of the Bitumen Booster Refiner results in the stability of bitumen. Thus making its use predictable in different temperatures and weather conditions.

THE WIDEST TEMPERATURE RANGE:

The BBR is effective in a 100°C temperature range and can be adjusted as required. – In the lower temperatures, the bitumen’s elasticity is increased, preventing it from cracking. In the higher temperatures, it is stiffer, not allowing it to melt to the sides exposing the aggregate.

HAIR LINE CRACKS:

Eliminate hairline cracks caused by the sudden drop in temperatures or automobile air conditioners' secretion pouring cold water on the hot asphalt surface. The 100°C effective range of the BBR provides you with that protection.

SOLVING THE RUTTING PROBLEM:

- The SBE reduces rutting problem by over 84% substantially increasing the life expectancy of the asphalt layer . - The only organic polymer that is environmentally friendly for the use of enhancing the qualities of the bitumen and asphalt layers in the world. Unlike petroleum based polymers that deteriorate with time the BBR increases in strength and durability. In addition, it resists water penetration.

NO NEED FOR SPECIAL EQUIPMENT:

The BBR does not require special equipment or specialized technicians to apply it. It is added directly to the bitumen as soon as it reaches its melting point.

BITUMEN VOLUME:

- The BBR increases the volume of bitumen up to 30% saving most of it’s cost and increasing the contractor’s profitability.

- The Syrian Government’s Sole Road Company registered an increase of 18.6% in that amount of asphalt. This results in savings of millions of dollars for the user country while increasing the profitability of the contractors.

WATER RESISTANCE:

- The BBR increases water resistance of both asphalt layer and bitumen prolonging its life expectancy. - It is the only binder in the world that makes the bitumen water resistant. It is the only binder in the world that makes the bitumen water resistant. All these features benefit both the end user and increases the profitability of the contractor.

EXECUTION TIME:

The BBR saves time as the asphalt layer is compacted immediately while it is hot and it will not stick to the steel drums of the compactor.

350% INCREASE IN THE ASPHALT LAYERS' LIFE EXPECTANCY:

- Bitumen is the glue that holds the aggregate together forming the asphalt layer. - BBR increases the volume of the bitumen i.e. the glue. It increases the durability of the asphalt layer by 350.

100°C EFFECTIVE RANGE:

- It is the only binder in the world that has a 100°C effective range. Ranging from - 22°C to + 82°C this one 100 range can be adjusted to go below 22 %.

PREVENTS THE DAMAGING EFFECTS:

- Kerosene Spillage. - Jet fuel Spillage. - It is the only bitumen binder in the world that makes bitumen and asphalt layers resistant to kerosene or jet fuel spillage.

REDUCES RUTTING UP TO 84.8%:

- Prolongs the life of the asphalt layer and increases its stability.